A Glimpse of Manufacturing Intelligence in Odoo with VPCS:

Manufacturing Intelligence (MI) refers to a system that integrate different sources of operational data confining to manufacturing for the purpose of deeper analytics, reporting, visual summaries and the sharing of data between enterprise-level and plant-floor systems to obtain some useful insights on the production system of the organisation.

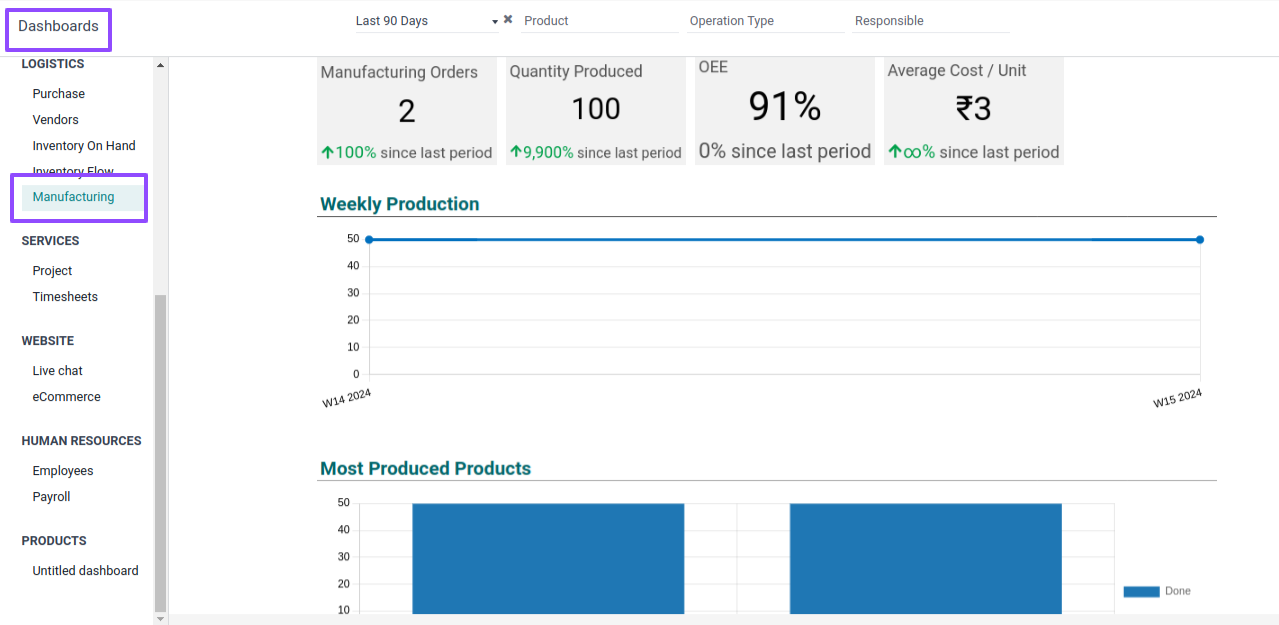

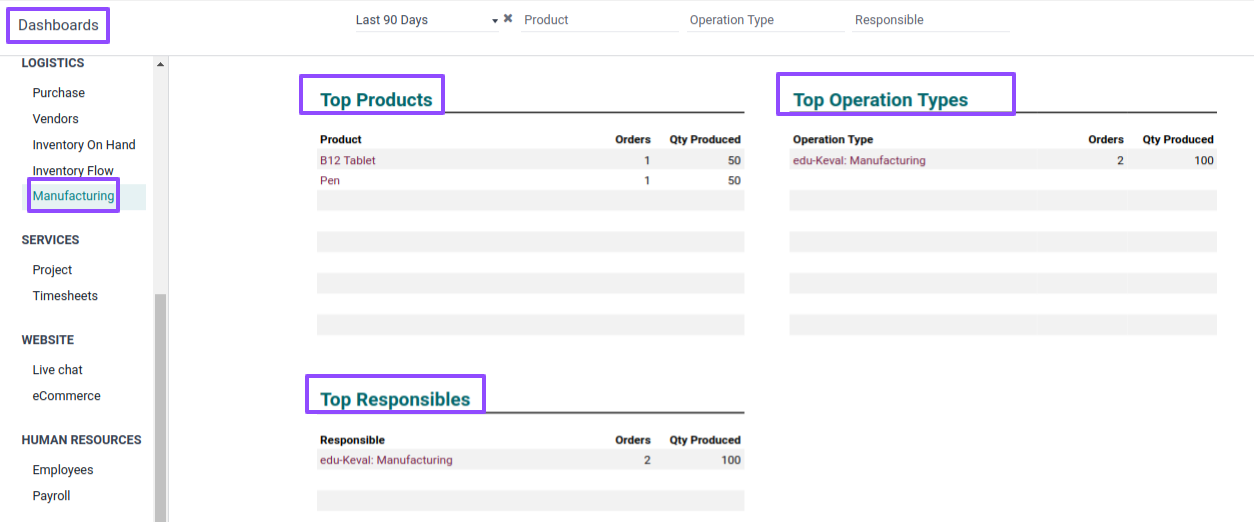

We have listed some Manufacturing Key Performance Indicators (KPIs) in context to Odoo to understand Manufacturing Intelligence, that can be used to generate useful information that can help in forecasting and decision-making for proposing any future sale orders that can be fulfilled on time and with the agreed terms.

The concept is demonstrated with an use case.

Use Case

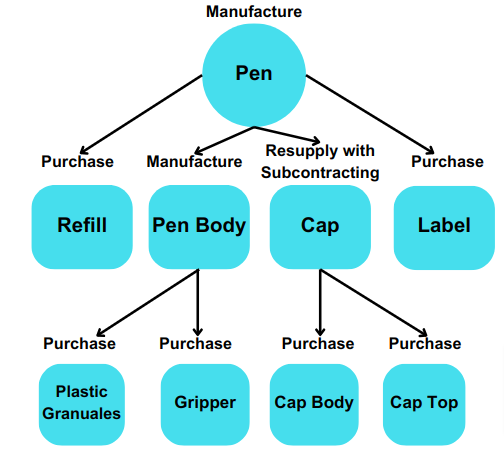

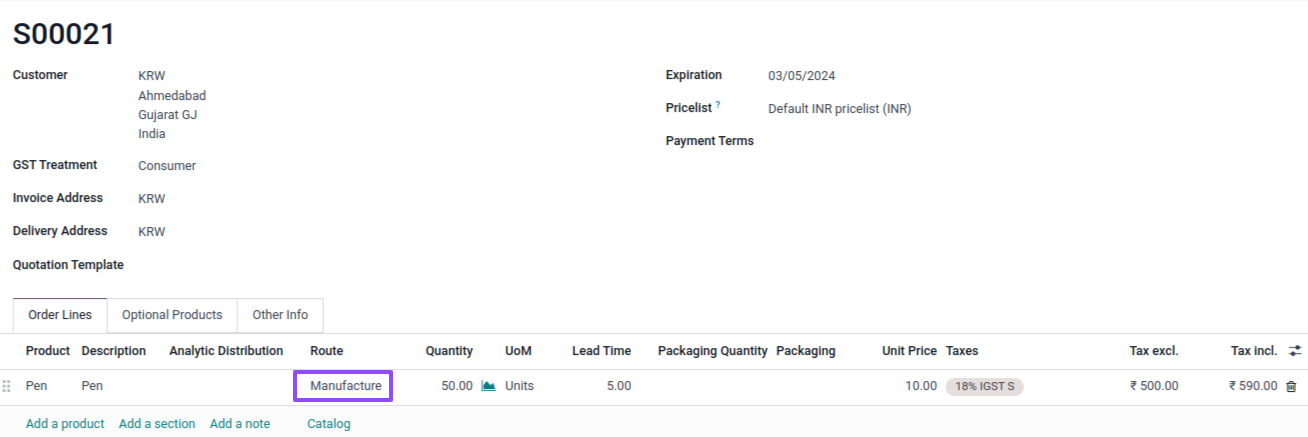

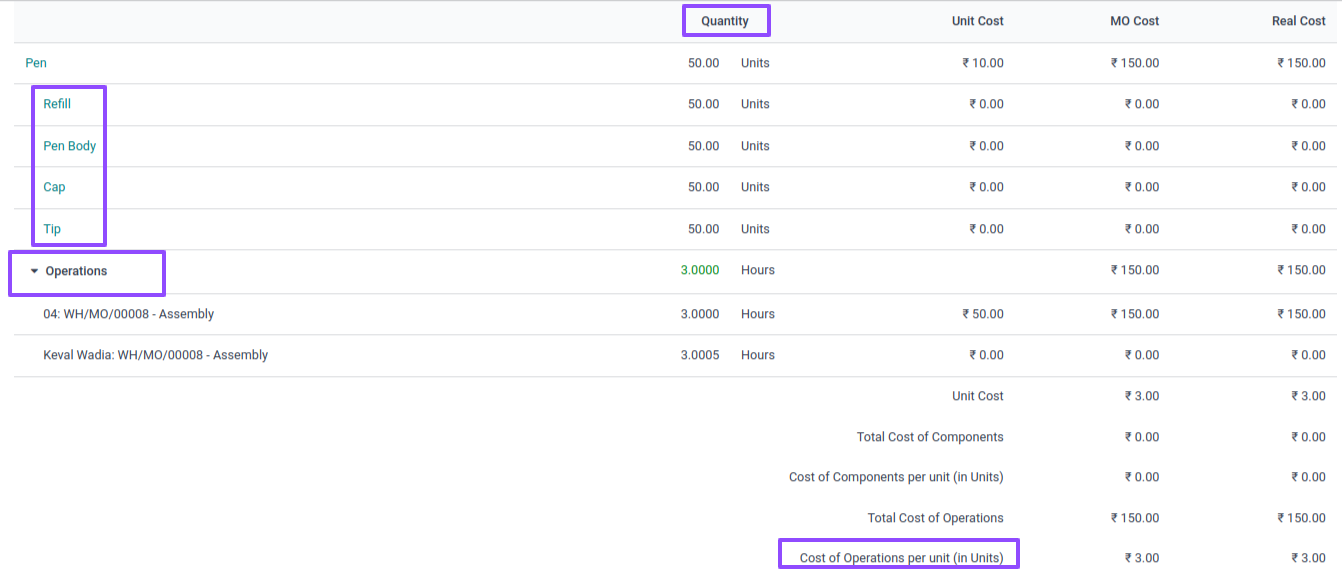

The use case is of manufacturing of a Ballpoint Pen. The product is detailed as below:

Manufacturing KPIs:

The Manufacturing KPIs here are classified into two groups which are Existing KPIs and Proposed KPIs.

Existing KPIs:

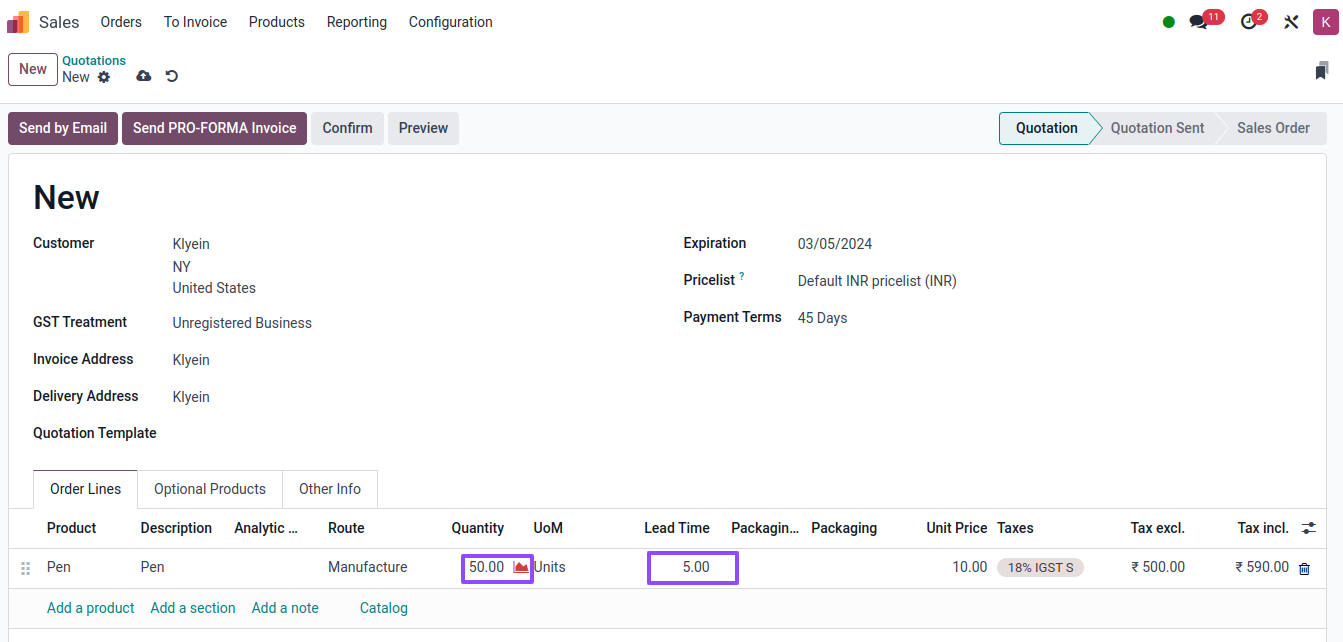

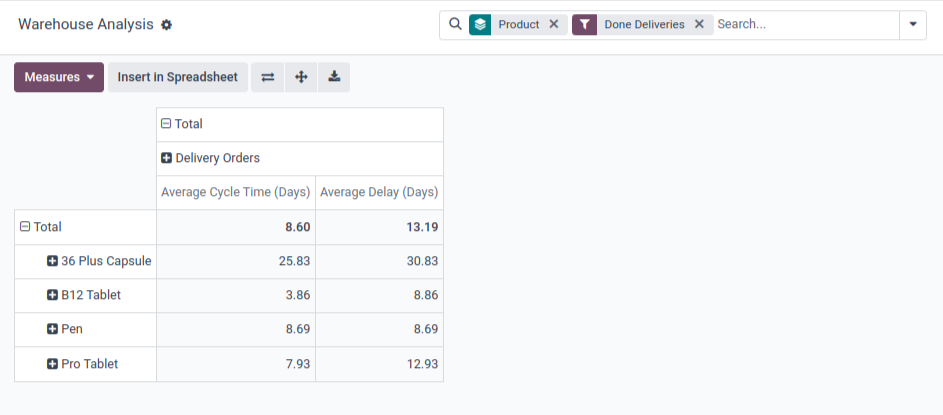

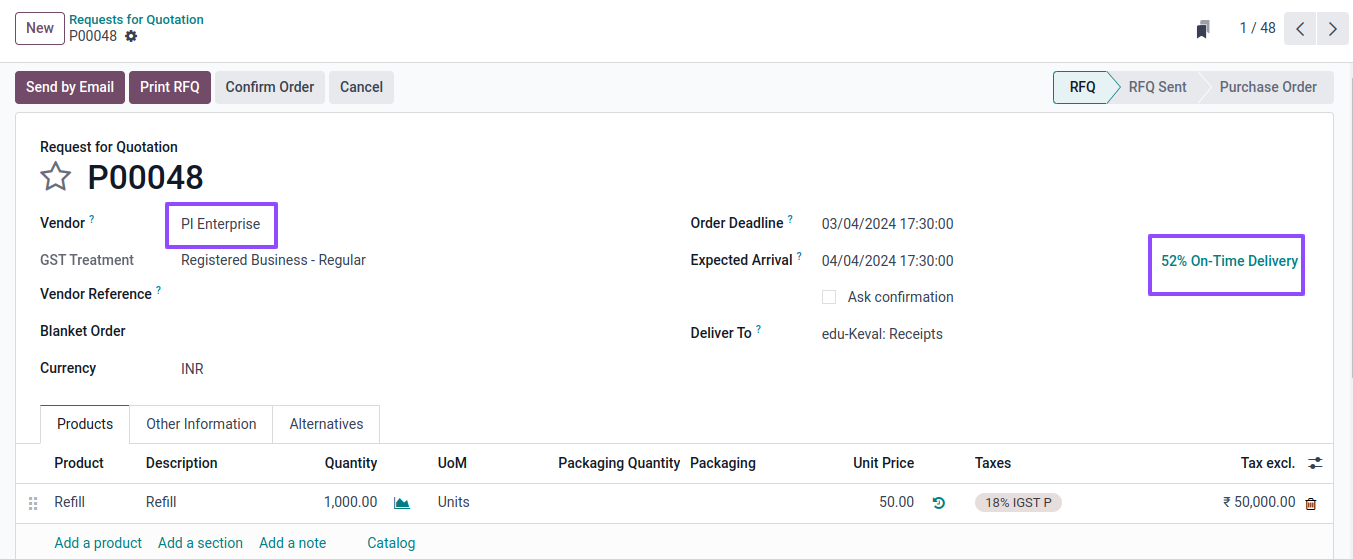

Lead Time: It is the time required to fulfill an order from the time it is being placed. The lead time can be a Purchase Lead Time, Manufacturing Lead Time, Sales Lead Time, Idle Time, Production Time and Customer Lead Time which are available in Odoo.

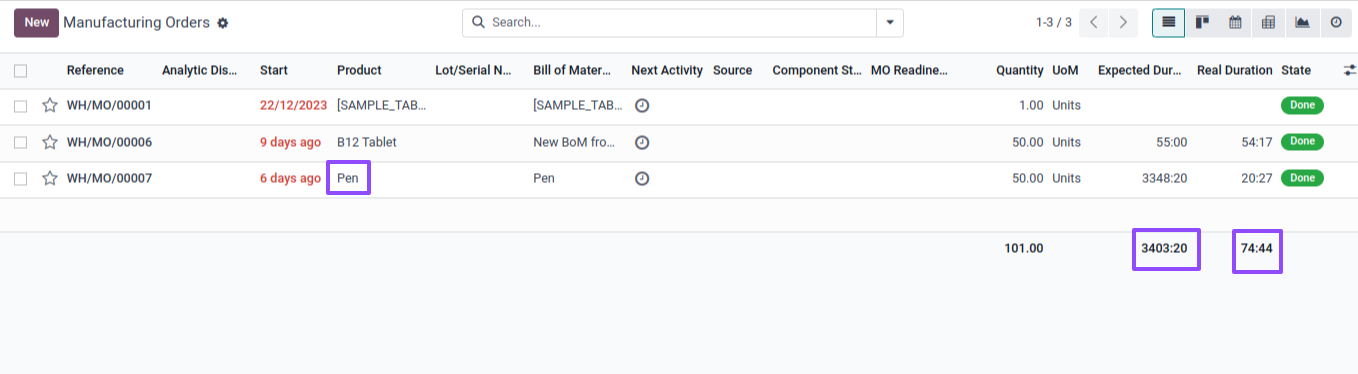

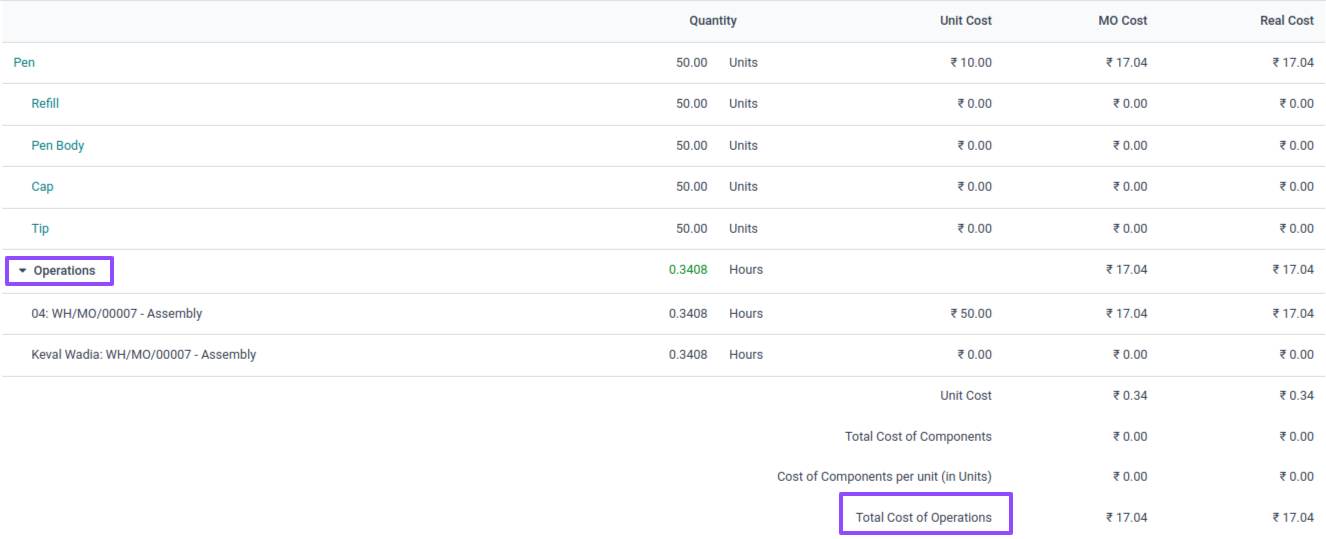

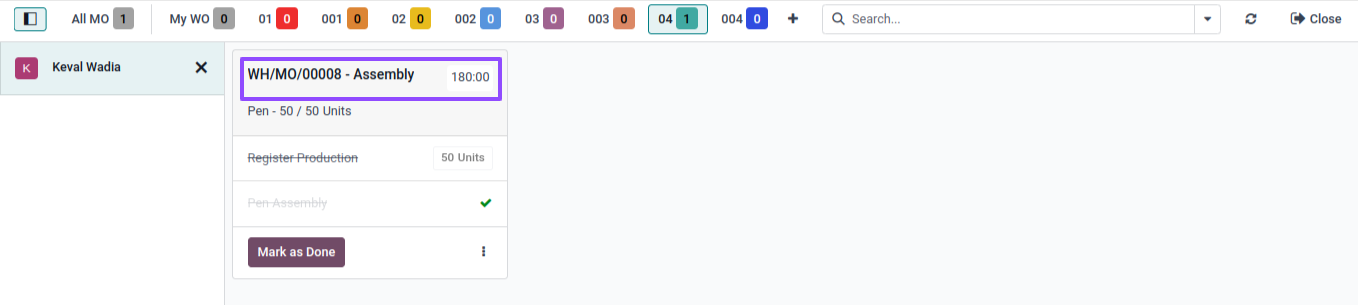

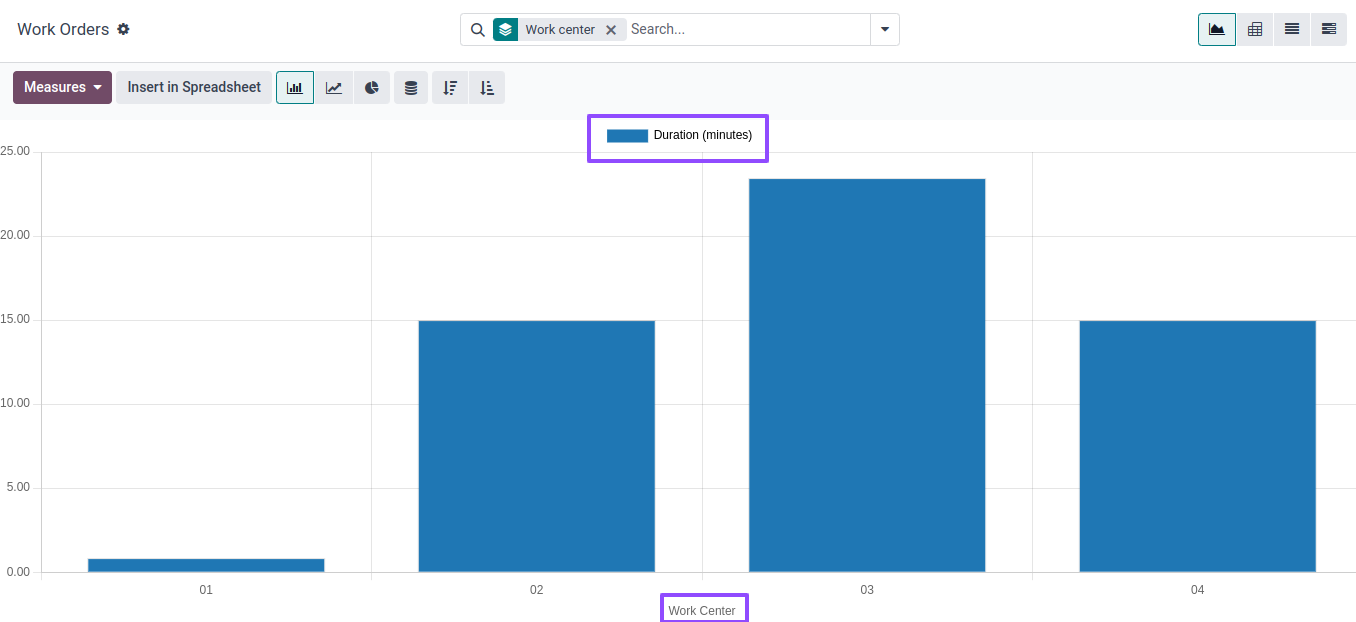

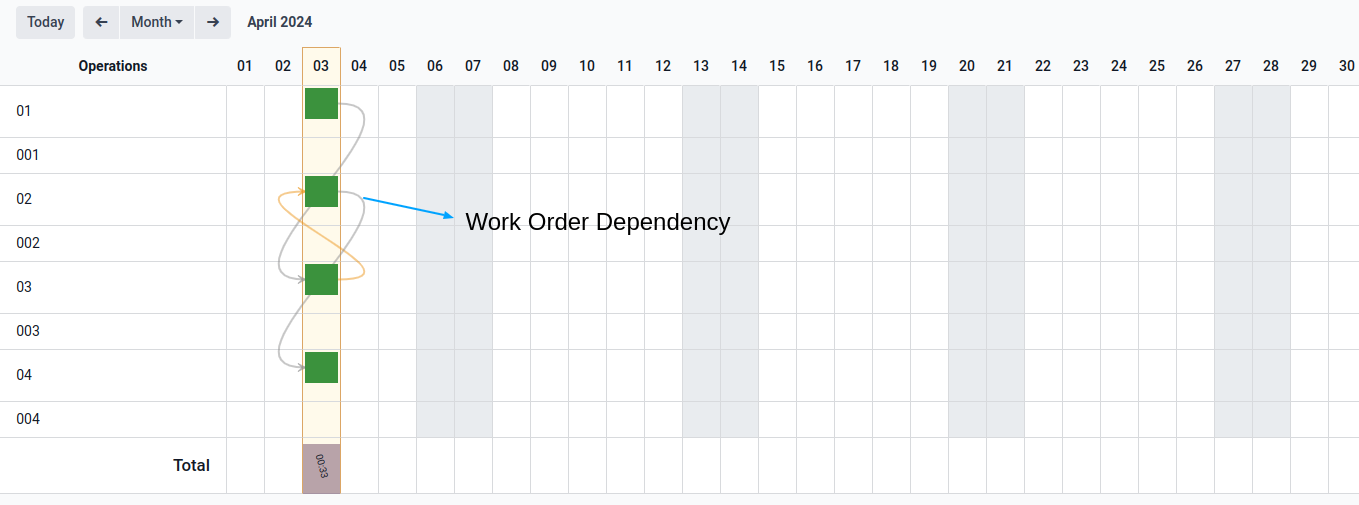

Production Time: The time required to complete one cycle of production from start to finish including the processing time, queue time, and wait time, changeover time, etc.

Work Order Performance: Odoo helps to track work order completion times, labor hours, and material usage to assess performance and identify areas for optimization.

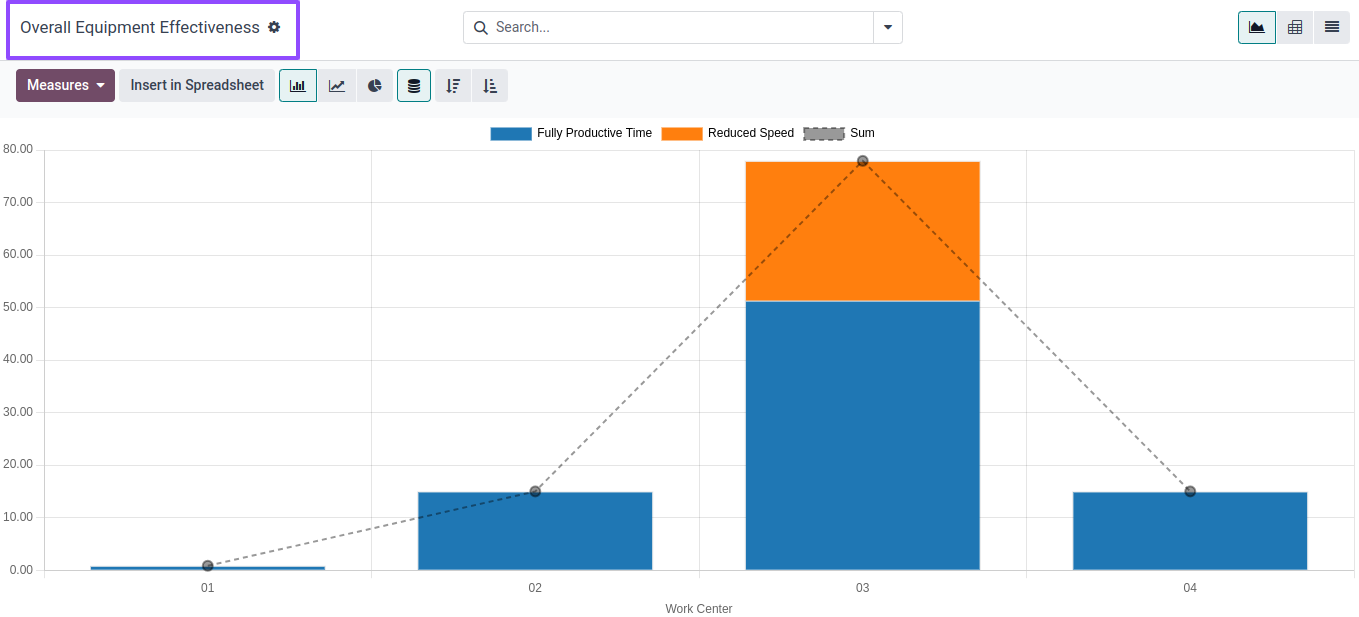

Resource Utilization: Odoo provides tools to track the utilization of resources such as labor, materials and equipments.

Proposed KPIs:

Specific Idle Time: Odoo doesn’t provide a detailed bifurcation of the idle time during the production like wait time, queue time, maintenance time and changeover time.

First Yield Pass(FYP): It shows the percentage of items that pass the quality control check in the first attempt.

Inventory Turnover Ratio: This KPI measures how quickly inventory is being sold or used up within a specific period.

Please give your reviews on the mentioned KPIs and also suggest KPIs other than those mentioned here and feel free to connect with us to discuss more on this topic!